Walk-in coolers and freezers are crucial fixtures in numerous industries, especially within food service and hospitality. While these two serve mainly to preserve perishable goods, they come with significant discrepancies in terms of temperature and usage. The differences between a walk-in cooler and a walk-in freezer can be key to how a business stores food and products, with implications for food safety and energy efficiency.

This article will explore the main differences between walk-in freezers and walk-in coolers.

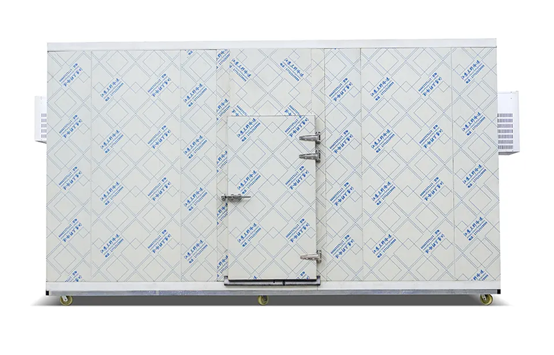

What is a walk-in freezer?

A walk-in freezer is a refrigerator for keeping food and merchandise below zero degrees Fahrenheit. Usually, it is somewhere between -10°F to -20°F (-23°C to -29°C) or even lower. This air-sealed large box equipped with a cooling unit ensures the inside remains chill.

Walk-in freezers consist of the primary parts such as the refrigeration coils, condenser units, compressors, and a temperature regulating mechanism. The evaporator coil draws refrigerant liquid, which absorbs heat from the inside of the deep freeze, and the compressor compresses this hot refrigerant gas, giving out its heat on the body of the deep freeze.

The absorption and emission of heat in this cycle maintain the desired interior temperature. A walk-in freezer often has thick insulation and sealed doors designed to help maintain consistent temperatures and minimize energy losses.

Walk-in freezers can store frozen products for commercial kitchens, supermarkets, and warehouses. Their small size makes staff easy to organize and search easily. In addition, they provide superior temperature stability and precision as compared to small refrigerators and ensure that products stay frozen at the right temperature for a more extended period.

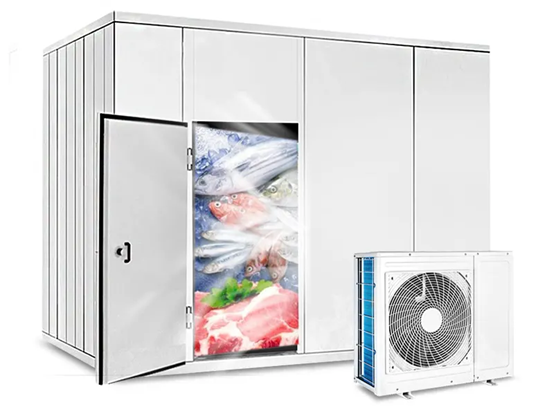

What is a walk-in cooler?

A walk-in cooler is a refrigerated storage unit mainly designed to keep foods and drinks that may decay if uncovered in warm weather situations. They commonly run between 32°F to 45°F (0°C to 7°C) or barely higher. These devices are utilized in several industries: food service, eating places, grocery stores, warehouse storage, and pharmaceutical garages. They are perfect for maintaining the shelf lifestyles of goods such as fruits and vegetables, milk, dairy, beverages, capsules,

Walk-in coolers use the same refrigeration concepts as freezers with the following components: evaporator coil, condenser unit, compressor, and temperature manipulate gadget. With stroll-in coolers, the main aim is to extract warmness from the inside to hold the preferred cool temperature. A condenser coil contains a refrigerant that absorbs warmth from the refrigerator.

The compressor compresses warm gaseous refrigerant and releases warmness from the unit through the coils, lowering the fridge’s internal temperature. Walk-in coolers have the right insulation and door sealing that keeps temperatures at the best stage, allowing products to remain clean and secure for consumption.

Walk-in freezer vs. walk-in cooler; what’s the difference?

1. Cost

Walk-in coolers usually have lower costs in terms of initial investment and running costs when compared to walk-in freezers. The difference in costs is due to the complexity of the cooling systems. Walk-in freezers require thicker insulating material and a more hefty compressor to maintain their subfreezing below zero temperatures. This leads to a costlier outfit and more power consumption. A walk-in freezer can cost around US$10,000 to US$30,000 or more.

Walk-in coolers work within higher temperature ranges and demand significantly lower energy usage, thus lowering operating costs. The cost-effectiveness associated with walk-in coolers is precisely why they are so popular among companies, keeping in check their short-term expenses and long-term operational costs. Walk-in coolers average about US$5,000 to US$20,000 depending on dimensions, level of insulation and added features.

2. Insulation

Walk-in freezers require more rigid and hardy insulating materials than refrigeration equivalents. And for good reason: there’s an extensive temperature range between what happens in the freezer and the ambient atmosphere. Some of the most widely used insulating materials for walk-in freezers are high-density polyethylene foam, XPS foam board, and fiberglass insulation. These materials provide high-level thermal insulation, allowing the cold within the freezer to remain constant.

Walk-in coolers require lower insulation values because of their ambient operating temperature. They are constructed from low-density expanded polystyrene (EPS) foam or lower-density polyurethane foam because it doesn’t need the same insulation thickness. Material selection affects the overall effectiveness and operation of the cooling equipment in every unit, thus making a walk-in cooler unique and distinctive in performance features.

3. Temperature range

Walk-in coolers usually keep the temperature 32°F-45°F (0°C-7°C) or slightly above. On the other hand, walk-in freezers usually operate at temperatures far below 32°F -10°F. Different temperature ranges dictate what type of product is stored in each unit. Walk-in coolers are perfect for foods that need to be refrigerated but not frozen, such as fruits, vegetables, and dairy products. The walk-in freezer is imperative for keeping frozen food items such as meat, seafood and ice cream.

4. Preservation methods

In a walk-in cooler, the primary preservation method is refrigeration, which inhibits microbial growth and enzymatic activity. Walk-in coolers preserve foods by maintaining products in moderately cold temperatures, usually between 32°F – 45°F (0°C – 7°C), which significantly prolongs the lifespan of perishable items, such as dairy products and fresh produce. The refrigeration method is essential to keep the product high-quality without deep freeze.

Walk-in freezers implement a more demanding procedure referred to as deep freezing. This method utilizes cooler temperatures, around -10°F to -20°F (-23°C to -29°C), with some methods even going deeper into hypothermia. Deep-freezing inhibits all microbiological and enzyme activity, thereby maintaining product shelf life for an extended time by preventing the development of spoilage organisms and allowing for gradual product deterioration.

5. Shelf life of products

Walk-in freezers are much more effective at extending the shelf-life of products than walk-in coolers because of the freezer’s super cold temperature. Frozen foods also possess a fantastic ability to retain their usability for months or even years without undergoing noticeable degradation in quality or spoiling.

In contrast, products in a walk-in cooler have a reduced shelf life as they can operate at just a few degrees under their decomposition point. While walk-in coolers extend the shelf life of certain items (fresh produce and dairy, for example) by several days, it’s undoubtedly not indefinite. Storage times in walk-in coolers generally vary, spanning anywhere from one or two days to upwards of several weeks, contingent upon product type.

6. Purpose

Walk-in coolers store perishable stock, including fruits, veggies, dairy products, beverages, and medicine. These items include those found in restaurants, grocery stores, pharmacies, and storage facilities for other products.

A walk-in freezer is constructed for the long-term storage of meats, seafood, ice cream and frozen vegetables. They’re typically used in food processing factories, supermarkets and commercial-size kitchens where large volumes of frozen items must be kept cool.

7. Cooling equipment

The cooling systems differ based on load and consumption requirements for each walk-in cooler and walk-in freezer type. Due to their lower temperatures, walk-in freezers require more robust compressors and longer evaporator coils. These systems are engineered to carry this extra load of freeze-holding, thus making the refrigeration units within walk-in freezers much more heavy-duty and energy-consuming.

Conversely, refrigeration equipment within walk-in coolers is designed to function at lower, but more passive temperatures, making it perfect for units that are both more energy-efficient and cheaper to run.

Final thoughts

Walk-in coolers and freezers differ not only in terms of the temperature but in many other aspects such as expenses, insulation, types of food preservation, shelf life, usage and type & capacity of the refrigeration system. Understanding these differences is helpful for food service, hospitality, and retail companies because they determine a vendor’s ability to provide product consistency, operational efficiency, and financial consideration.

For those looking to buy commercial refrigeration systems such as a walk-in cooler and walk-in freezer, look at the choices available on Alibaba.com.

Leave a Reply